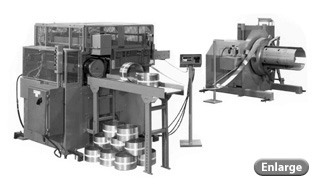

The Roll Valley Machine

feeds sheet, automatically measures, winds, cuts, tapes and ejects

Roll Valley stock from master coils. The cycle time is 27 seconds

for a 50’ coil, and the desired number and length of coils may be

programmed.

Pneumatically controlled, the machine can run ferrous or

non-ferrous metals. AC Drive. 8 inch & 10 inch models available.

Coil widths from 6” to 36”. Produces taped coils from 50’ to 300’

lengths with maximum material thickness of 28 gauge mild steel or

.024 aluminum. |

|

|

8” or 10” Roll Valley Machine

& Decoiler |

|

|

|

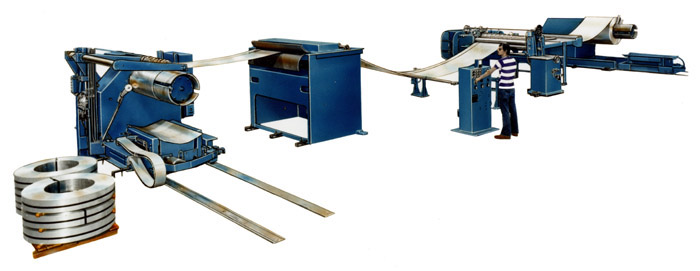

Slitting Line 20,000#

Capacity, 60 Inch Maximum

Two models handle 48” or 60” Coil

Stock – 20,000# capacity. The Slitting / Rewinding Line

automatically slits uniform production-width strips and rewinds to

100% tight coils. The Tensioning Unit keeps proper tension on

individual strips during rewinding to assure uniform coil

tightness. Mild or equivalent non-ferrous material can be slit to a

minimum of

1” |

|

|

|